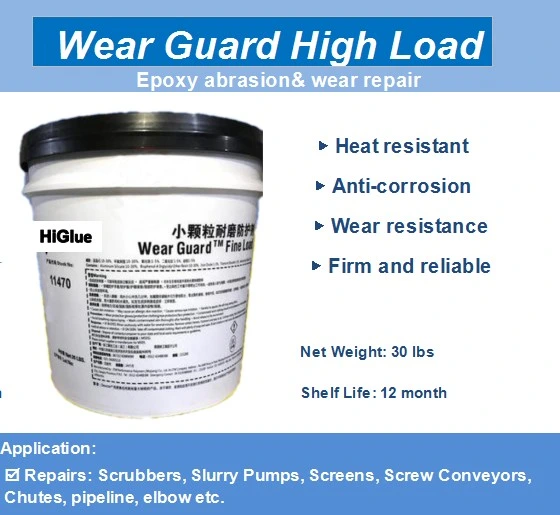

Higlue 11470/11490 Abrasion Resistant Coating, Epoxy Ceramic Wearing Compound

Ceramic Filled Epoxy/ Corrosion Repair Wearing Compounds Ceramic beads filled epoxy repair putty is made up of high perf;

Basic Info

| Model NO. | 11470 |

| Material | Epoxy |

| Classification | Room Curing |

| Main Agent Composition | Wearing Compound |

| Characteristic | Wear Resistance |

| Promoter Composition | Curing Agent |

| Composition | Inorganic Material |

| Color | Grey |

| Transport Package | Carton |

| Specification | 10kg |

| Trademark | Higlue |

| Origin | Jiangxi China |

| HS Code | 3506100090 |

| Production Capacity | 20000PCS/Month |

Product Description

Ceramic Filled Epoxy/ Corrosion Repair Wearing Compounds Ceramic beads filled epoxy repair putty is made up of high performance wear resistant and wear resistant ceramic particles and modified toughening and heat-resistant resin.Ceramic beads wear resistant epoxy coating is widely used in repairing all kinds of wear parts and preparing wear-resistant and corrosion-resistant coatings on the surface of all kinds of machine parts. For example: repair and pre-protection of pipeline, elbow, mud pump, sand pump, centrifuge, packing box, slurry circulating pump body, impeller, size head of power plant desulfurization system, etc.Features:

1. Ceramic-filled for outstanding resistance to abrasion;

2. Renews worn surfaces fast-reduces downtime;

3. Extends wear life- resists sliding abrasive wear and eliminates costly wear part inventory;

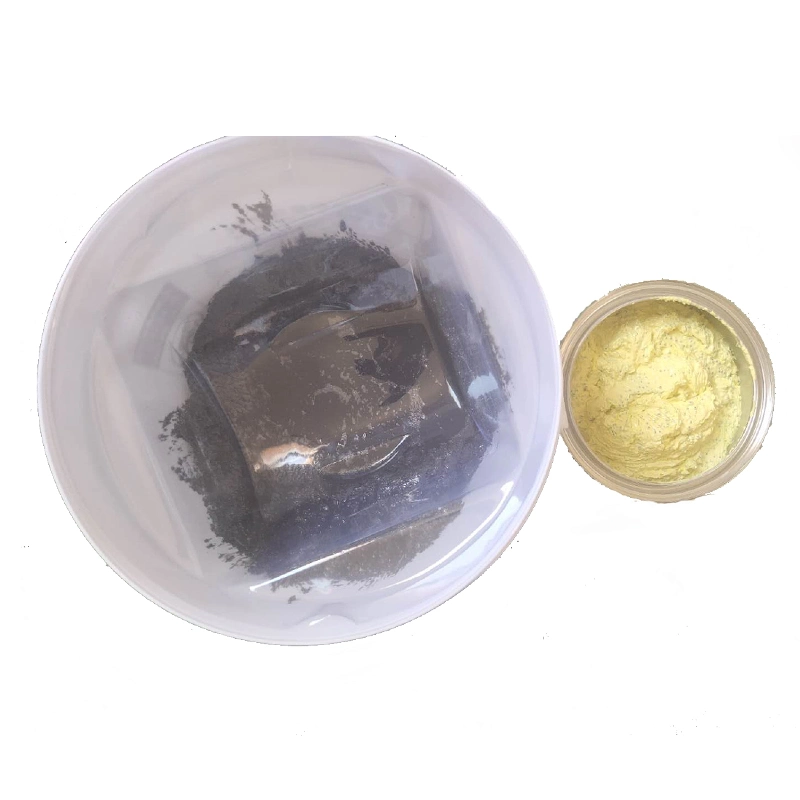

4. Non sag- provides abrasion resistance on over-head and vertical surfaces.Ceramic Repair Putty* Renews worn surfaces fast and reduces* Downtime to put equipment back in service* Quickly Easy to mix and use* Non-sag paste allows application* Versatility for overhead& vertical surfaces* Non-shrinking* Extends wear life* Resists sliding abrasive wear* Eliminates costly wear part* Inventory Can be re-applied to* itself Contains ceramic beads 1-1.5mm.Technical Information

| Product Type | Ceramic Repair Putty/ Abrasion Resistant Coating/ Wear Resistant Epoxy |

| Resistant Properties | Corrosion-Resistant |

| Pear Dia. | 1- 1.5mm (can be customized) |

| Color | Grey (can be customized) |

| Mix Ratio by weight | 8:1 |

| Mix Ratio by volume | 4:1 |

| Working temperature | 149ºC |

| Package Weight | 30 lb per kit |

| working time | 45-65 mins |

| Compressive strength(GB/T1041): | 112.0MPa |

| Tensile strength(GB/T6329): | 32.0MPa |

| Shear strength(GB/T7124): | 14.0MPa |

| Flexural strength(GB/T9341): | 45.0MPa |

| Fully curing time | 16-24 hours |

| Shelf Life | 12 month |

Application

1. Cyclone and separator bodies

2. Dust collectors and exhausters

3. Pump liners and impellers

4. Fan blades and housings

5. Chutes and hoppers

6. Elbows and transition points

How to use

1. Surface treatment: roughening the parts to be treated, sanding or sandblasting with an angle grinder, etc.; cleaning the roughened surface; the treated surface should be a rough and dry fresh substrate surface, and should be No oil and dust.2. Preparation: Mix the components A and B of the small particle wear-resistant protective agent according to the mass ratio A:B=2:1, and use them within 30 minutes.3. Coating: apply the uniformly mixed small particles of wear-resistant protective agent layer by layer to the area to be repaired, preferably at a thickness of 3-10 mm. The adhesive layer should be compacted to fully infiltrate the substrate; after the coating is applied to the required size, the surface layer is smoothed.4. Curing: Curing at 25ºC for 16 hours can be put into use. When the temperature is lower than 10 degrees, it can be cured by baking with an iodine tungsten lamp or electric heating plate for 2 hours.

Packing & Shipping 500g/set, 5kg/set, 10kg/set, 13.7kg/set and 20kg/set10kg/set carton size: 32x32x32.5

Our Company

Q: Are you trading company or manufacturer ?

A: We are factory which over 20 years of experience,and provide you direct prices

Q: Can I be your agent?

A: Sure, we are looking for agent all over the world

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: If I am not satisfied with the products ,when I get it,what should I do?

A: If not satisfied it, please feel free to contact salesman soon, we will provide you the solution ASAP.

You may also like

Send inquiry

Send now